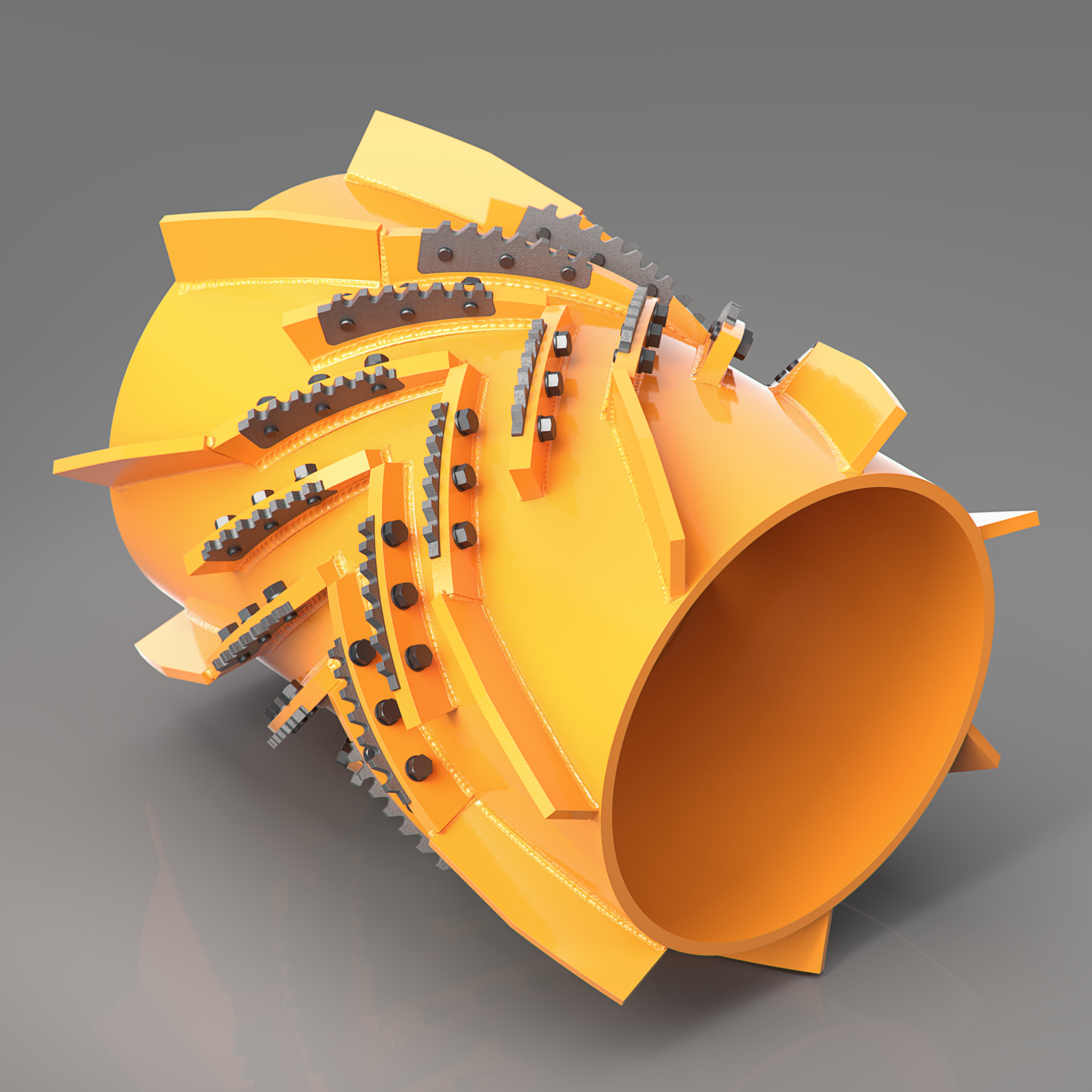

Debarker Feedrolls

Webco debarker feedrolls are manufactured with the highest quality workmanship and are made custom to perform in the specific environment that your debarker is facing. We recognize that every debarker is facing different challenges— whether it’s harsh conditions and extreme wear or plugging and traction issues, we work with our customers to come up with a specialized feedroll solution.

TRACTIONPRO FEEDROLLS

WITH REPLACEABLE INSERTS

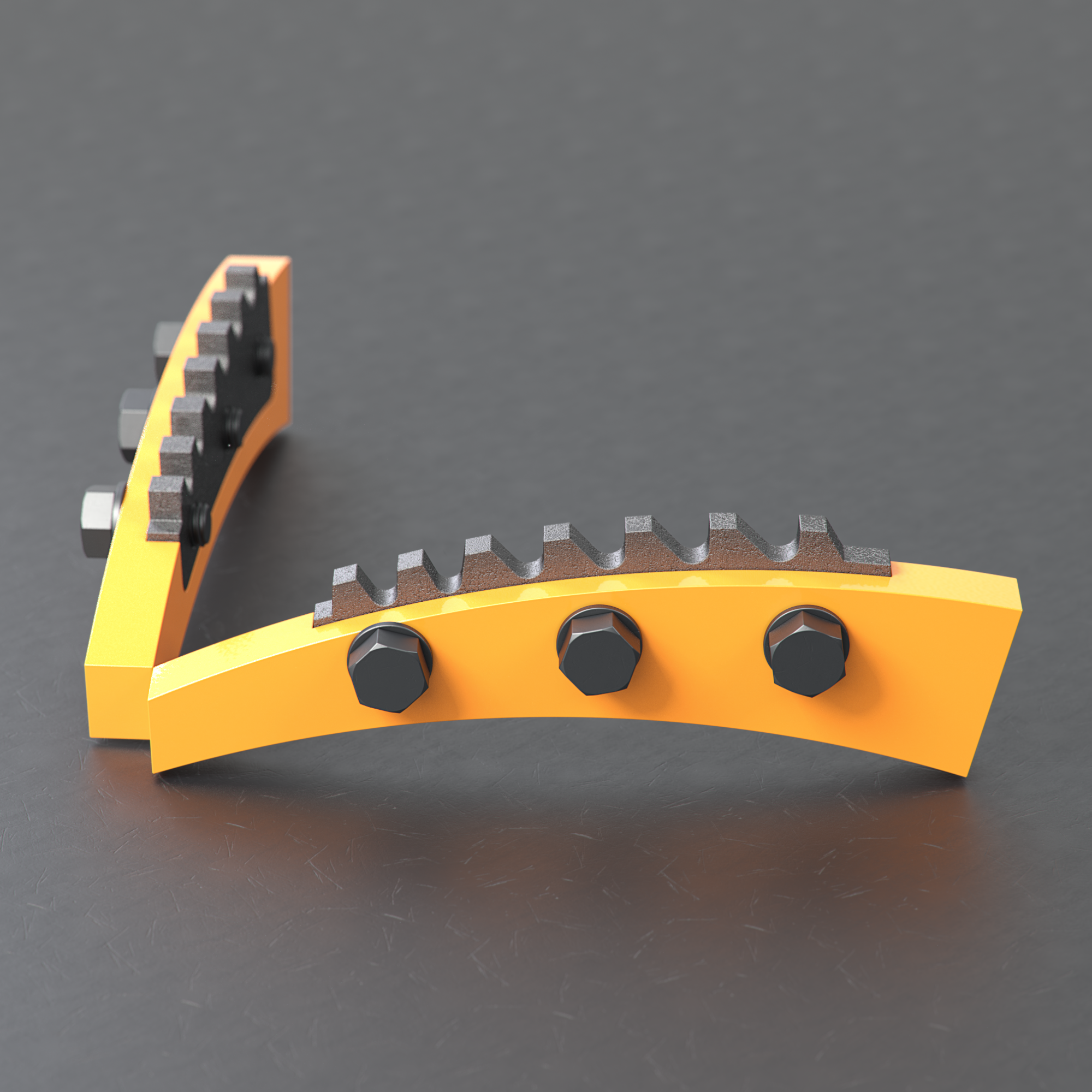

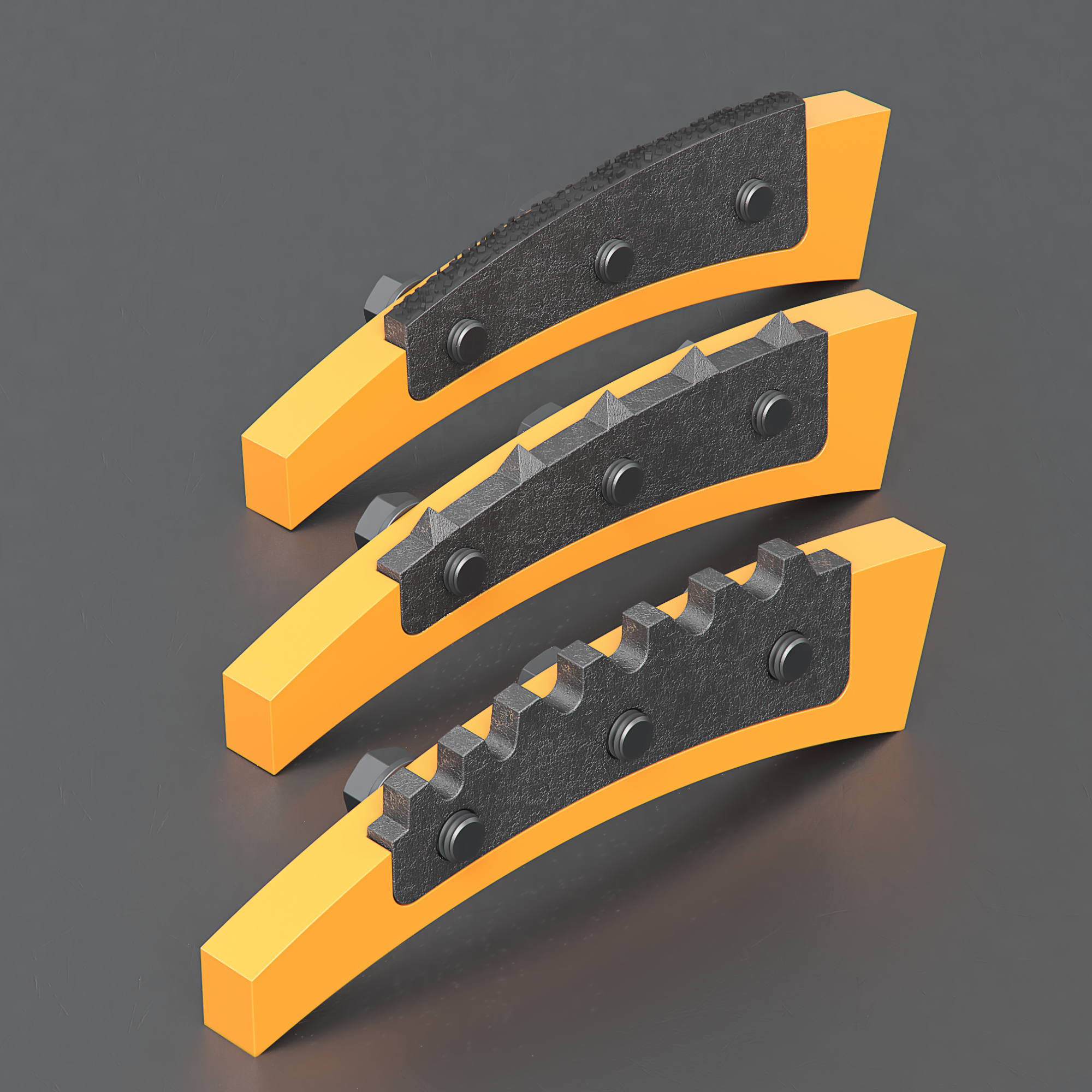

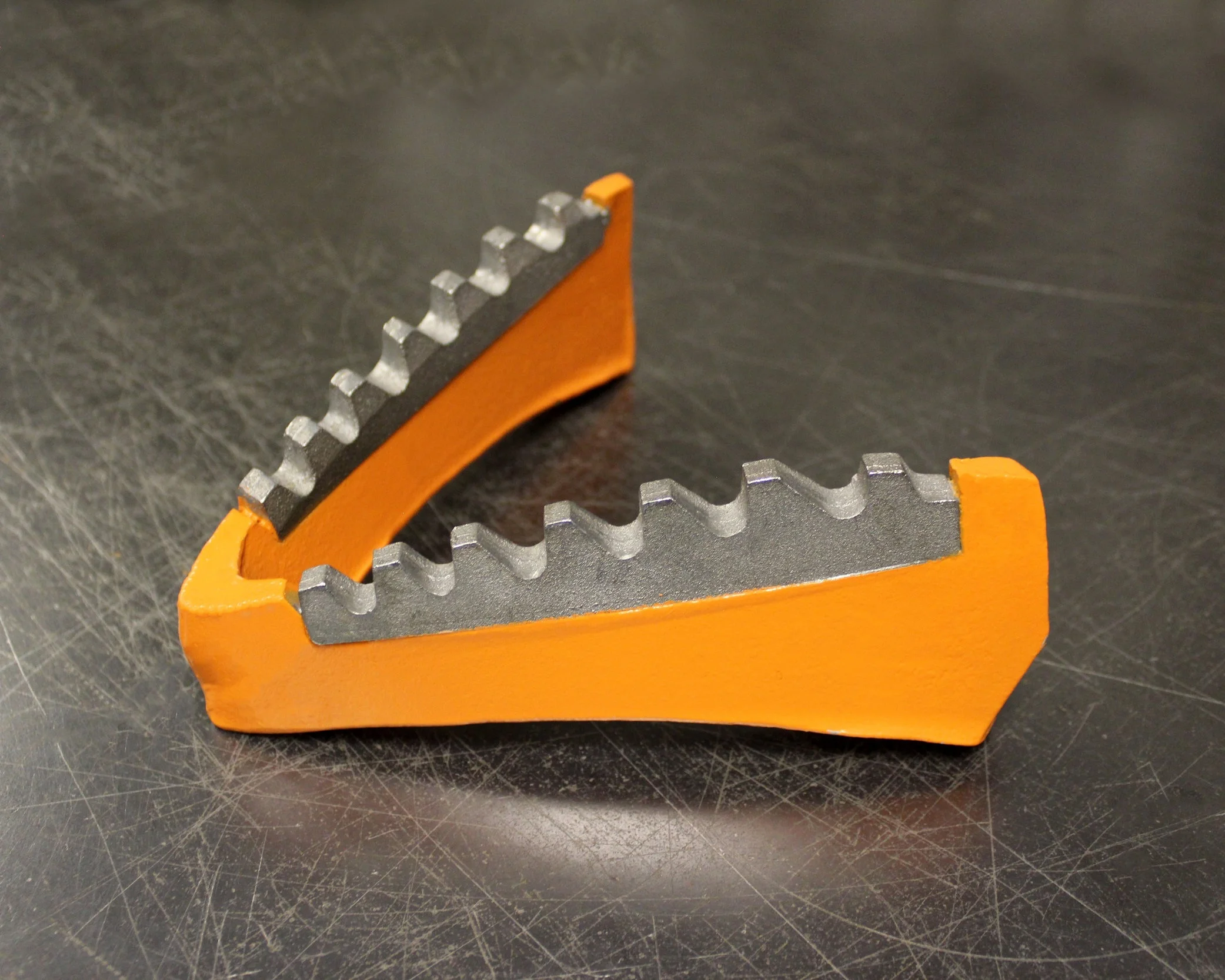

TractionPro Feedrolls with replaceable inserts provide a longlasting, effective and convenient solution to keep up with debarker feedroll maintenance and performance. Extremely durable, high alloy replaceable inserts stand up in harsh conditions, ensuring a superior grip of logs and debarking efficiency. Inserts are available in three different options including: Serrated, Spiked, and Carbide A.R.M.

TRADITIONAL FEEDROLLS

NEW + REPAIRS

Webco both manufactures new and repairs worn and damaged debarker feedrolls. New replacement feedrolls are manufactured with high alloy flights and are available with different flight options, including Spikes, Carbide A.R.M. and High Alloy Traction Elements. We also specialize in debarker feedroll repairs and offer many solutions to make them even stronger and more durable than their original state. We assess the rolls and identify the extent of the wear and determine if flights require replacement or build up.

Webco supplies a range of flight options for debarker feedrolls. Depending on the debarker you are using in your sawmill, there are different solutions that work best for each type of feedroll. The spacing of the flights on the roll or even whether the roll is being used on the infeed or outfeed can determine which flight will work best. If you’re unsure which flight options are right for your machine get in touch!

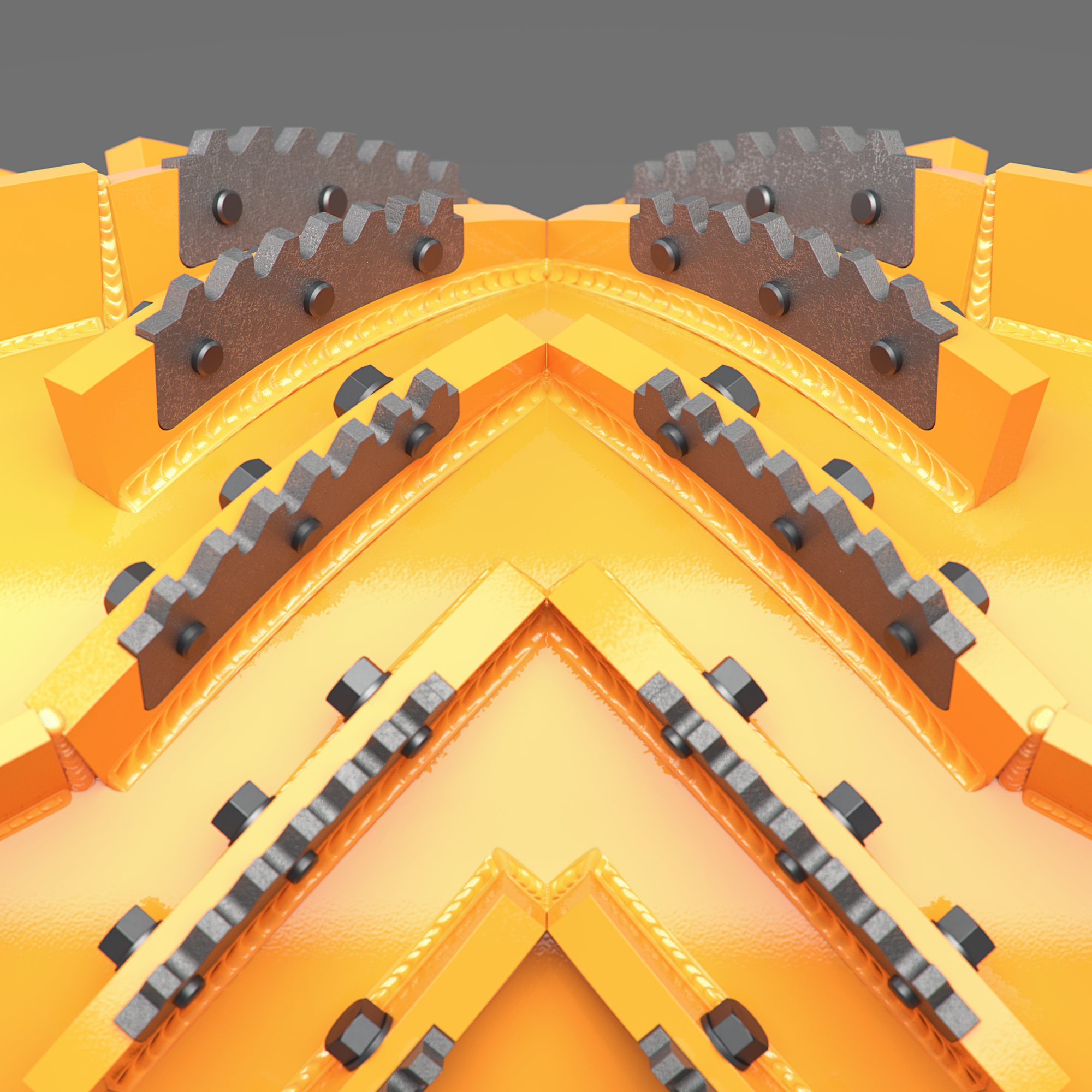

A solution for traction and plugging issues

Many flights on the market are made of lower quality material and they quickly wear down to a smooth surface. Our solution to this is our High Alloy Traction Element flight design with deep grooves and high alloy material, providing long lasting traction for as long as 24 months in use.

Another issue that debarking feed rolls often face is plugging. Some designs have too many flights that are placed too closely together and they often get plugged up with debris which in turn reduces traction, causing a host of issues within the debarker. Our solution to this is reducing the number of flights to allow more space in between. One of our customers sent us some pictures of the difference between our High Alloy Traction Element feedrolls compared to an original design feed roll run at the same time which shows how the difference in design can eliminate these issues altogether: