Custom Projects

Slide Bars - Sawing / Profile Machines

We know how much of a labor intensive job it is to change out the slide bars in your sawing machines, therefore Webco has created carbide slide bars for your Comact DDM and Hewsaw machines. The carbide wear proofed ridges will maximize your slide bar life and last 6x longer than original.

Webco Comact DDM 2pc Carbide Slide Bar

Webco Hewsaw R200 Carbide Slide Bar

Log Turner Bit

Designed for the Cleerman log turner. Body is manufactured from T1 steel and upgraded with oil-less bushings in the bore. The 2pc assemble takes a double sided carbide tip with high impact carbide wear proofing the front edge exposed to extreme wear. These quality upgrades will greatly increase the lifespan of the part — up to 5x times longer!

Canter / Slabber Parts

Webco manufactures new and wearproofed anvils, guide bars, shoes and other miscellaneous parts for canters and slabbers. We also offer hardened tool steel, carbide inserts and extra chrome build-up in the high wear locations to maximize wear life. We can also repair these parts to provide wear resistance at a fraction of the cost of new parts. Parts are available for Comact, HewSaw, Optimil and USNR (Kockums Cancar) machines. If you have the make, model and size of your machine ready and we can help you order the right parts.

tong loader arms

Original tong loader arms often wear down quickly on the PLC 200 tong loader machine and are in need of repair. We’ve found that by machining a pocket and braising in carbide, the loader arms are better than new and rarely need another repair due to the sharp carbide edge.

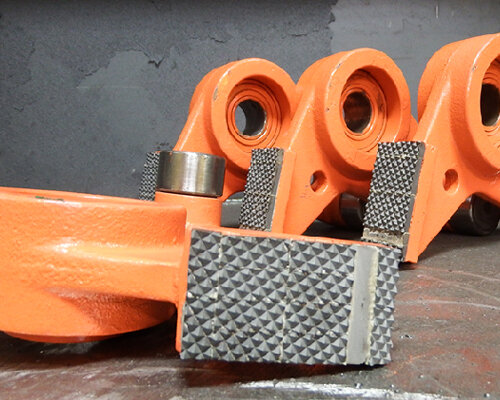

LUG LOADER SHOES

Lug loader shoes are often repaired on site with a commonly used tool kit. Issues arise with the shoes getting clogged with pitch. At Webco, we repair the shoes with our own carbide grippers that are designed to reduce clogging while maintaining a strong grip.

Clogged Loader Shoe

Webco Carbide Gripper

Chipping Head Repairs

Hardened wear inserts or carbide inserts can be installed in high wear areas for additional wear proofing. These repairs provide wear resistance at a fraction of the cost of new parts and significantly extend the life of the part. Below is an example of Andritz/Iggesund style chipping segments that we repaired. On the left is an original tip that was in service for 3 months and on the right is one that we repaired with a tool steel insert that was in service for 11 months. The repair lasted over 3x times longer than the new tip and wore down smoothly, in a way that did not affect chip quality.