Webco Frozen Febuary

Frozen Bark Solutions

4 METHODS TO Battle frozen bark

It’s that time of year again, as the seasons change and we find ourselves in the midst of winter. Temperatures have dropped significantly, and the snow is now steadily falling all around us. This seasonal shift also means we’re increasingly seeing more breakage in sawmills, which can lead to a significant mess, extended downtime, and a lot more maintenance if we’re not set up for it properly in advance.

To help mitigate these issues, we offer the following suggestions:

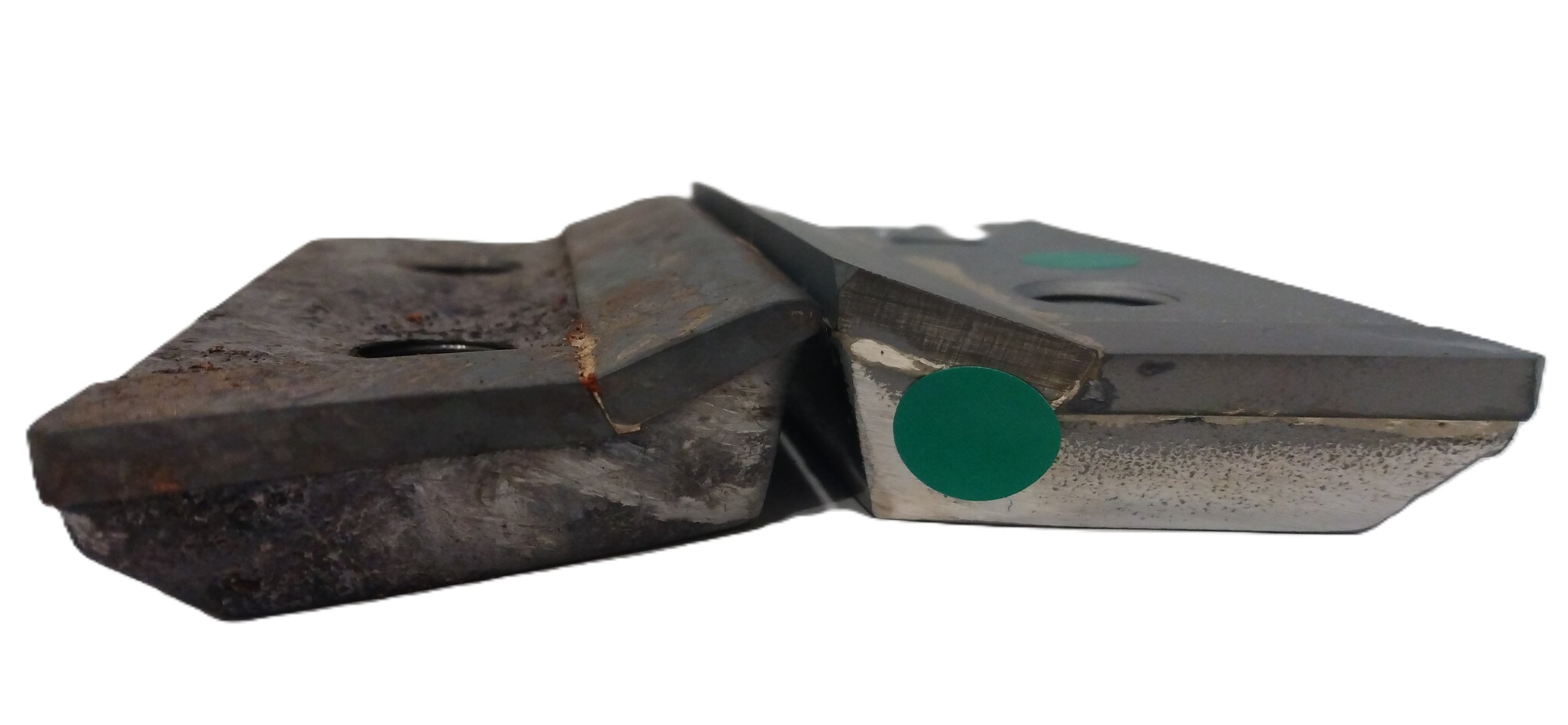

Sharp Tips

So why is it so important to have sharp debarker tips? Well, first and foremost, sharp debarker tips are more effective at removing bark. When the tips are dull or damaged, they are not able to cleanly cut through the bark, leading to incomplete removal. This can slow down the processing time and result in lower quality debarked logs. Not to mention increased arm pressure to battle a dull tip will lead to more machine wear and higher breakages. Additionally, using sharp debarker tips can also help protect your saw blades. When the bark is not completely removed, it can get caught in the saw blade, causing friction, heat and potentially damaging the blade. This can lead to more frequent sharpening or replacement of the saw blades, which can be costly and time-consuming as we all know.

Steeper Angle

No different than finishing blades having a steeper angle that allows for cleaner, smoother cuts when compared to ripping blades, which usually have lesser angles suited for faster, rougher cuts. Similarly, debarker tips are designed with various tip angles that are tailored to effectively work with the bark and the specific season. For instance, during the winter months, when freezing has caused all the dried-on bark from the summer to harden that much more to the log, it calls for the most aggressive angles to effectively get underneath that stubborn frozen bark. As a result, most mills located in British Columbia and Alberta will typically operate with a 20 to 24-degree tip during these frigid months, depending on the particular machine they have in use. Additionally, we have the capability to manufacture custom tips that can reach up to 30-degree angles for specialized purposes and unique applications.

Scoring Tips

Traditionally for stringy bark but scoring tips can be very effective as a first line of defense to break up hard frozen bark. Depending on the tip you’re running and the conditions you’re facing, a great solution is to add extra scoring pieces to make the most of the surface area of the tip to cut the bark. Many of our customers have seen great results with this option.

Feed Speed

Faster production speeds may indeed enhance log volumes, but this increased velocity can inadvertently lead to a significant loss in value at the very first production step. It is essential to find a balance between speed and quality to ensure that the sawmill operates optimally without sacrificing the quality of the initial processing stage, debarking.

During the colder winter months when frozen bark is typically present, the most significant suggestion for sawmill operators is to reduce your feed speed, maintain a medium arm pressure and have sharp tips. This speed adjustment increases your overlap, which results in better quality debarking while also minimizing the tear-out and fiber damage that is often prone to occur with dry bark frozen in the negative temperatures. While it is true that production rates will be reduced during this time, rest assured that the better quality debarking achieved will ultimately lead to an increase in your overall sawmill efficiency and profitability during the winter months..

If you’re dealing with frozen bark issues that are impacting your production and efficiency, we are happy to help you come up with some customized solutions. Email or call us to find out more.