CHIPPER PARTS

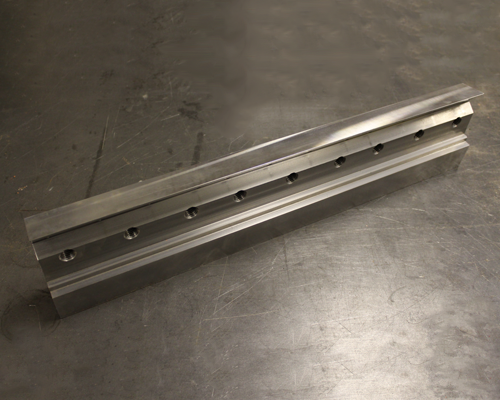

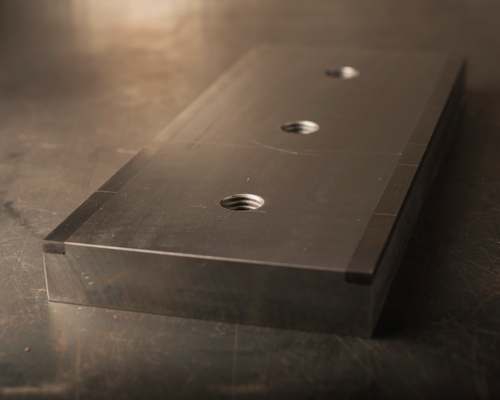

cLAMPS, COUNTER KNIVES + HOlders

Webco manufactures a variety of new knife clamps, knife holders and counter knives for disc, drum and veneer chippers from high alloy wear plate for long-lasting durability.

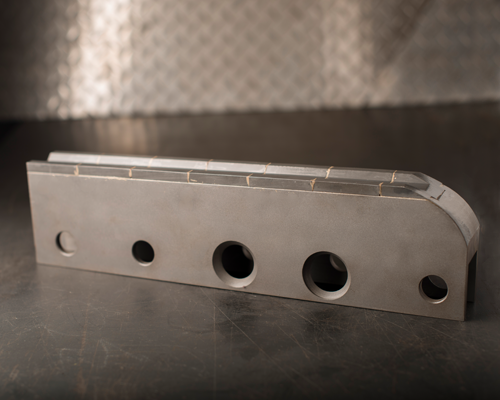

Carbide Anvils + Wear Plates

Being manufactured from AR-400 wear plate with a carbide insert, Webco carbide chipper anvils will last from 4 to 6 times longer than a welded-hard faced anvil. Because a carbide anvil holds it’s sharp edge longer, it cuts the chips more cleanly, reducing compression damage. Our customers report chip quality improvement while running carbide chipper anvils.

Chipper anvil design is excellent for carbide application because the angled lead edge presents a blunt carbide brazed edge to the chipper knife, reducing debris damage to the anvil. Also, the carbide grade is important—harder is not always better. We use a softer, tougher, shock-resistant grade of carbide than what is found in saw tips. Our specialized brazing technique guarantees a solid bond between the carbide and the steel, ensuring that heavy debris does not knock it loose.

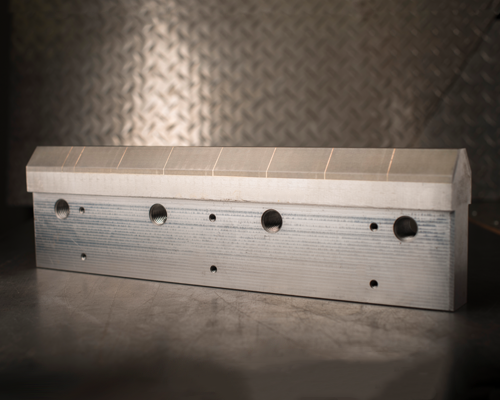

CHIPPER PART REPAIRS + WEARPROOFING

In addition to newly manufactured parts, we also repair counter knives, knife clamps, knife holders and other miscellaneous parts for disc, drum and veneer chippers. Hardened wear inserts or carbide inserts can be installed in high wear areas for additional wearproofing. These repairs provide wear resistance at a fraction of the cost of new parts and significantly extend the life of the part.

Below is an example of Andritz/Iggesund style tips that we repaired. On the left is an original tip that was in service for 3 months and on the right is one that we repaired with a tool steel insert that was in service for 11 months. The repair lasted over 3 times longer than the new tip and wore down smoothly, in a way that did not affect chip quality.

Looking for something else?

We supply many different styles of vertical/side anvils, horizontal/bottom anvils, feed plate/spout anvils, wear plates and liners.

Contact us to find out more.